The art of granite joints

We are building a new production site in Tianjin. The facade of the two buildings will be covered in natural stone. We will use the same grey granite as we used to cover our floors in other EUROIMMUN buildings.

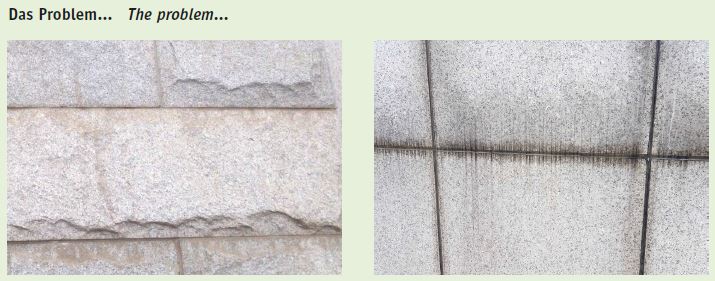

If you have a look around, you often see dirt in the joints of natural stone facades, no matter whether these are filled with plaster or silicone or are open. This is due to dust accumulating on the upper edges of the stone plates which is then washed down by the rain. This causes ugly “adornments”, most often as irregular bands running downwards, but also sometimes upwards and towards the sides due to diffusion.

If you have a look around, you often see dirt in the joints of natural stone facades, no matter whether these are filled with plaster or silicone or are open. This is due to dust accumulating on the upper edges of the stone plates which is then washed down by the rain. This causes ugly “adornments”, most often as irregular bands running downwards, but also sometimes upwards and towards the sides due to diffusion.

In Tianjin, we are trying out something new. The granite plates are cut in an angle so that no dirt can collect on the upper edge. The joints point downwards from the building at an angle. They do not have to be filled with plaster or silicone since the rain runs out and downwards. This “new openness” also leads to a good rear ventilation of the facade and no humidity builds up in the masonry. We expect our facade to remain clean for a long time and our approach to serve others as an example.

Furthermore, applying these stones according to the present invention leads to an especially consistent and beautiful pattern of the joints. Whether this method actually serves the purpose remains to be seen. We will let dust, rain and frost have their effect for two or three years and then present the result.